Comparison and Application of Galvanized and PPGI White Sheets

Galvanized sheet metal and PPGI (pre-painted galvanized steel) are two materials commonly used in modern industry and construction. While they both offer good corrosion protection, there are significant differences in application, performance and appearance. This article will provide a detailed comparison of these two materials to help readers better understand their characteristics and application scenarios.

First, the definition and characteristics of galvanized sheet

Galvanized sheet refers to a layer of zinc coated on the surface of the steel plate to improve its corrosion resistance. The galvanized layer forms a protective barrier that effectively prevents the steel from coming into direct contact with moisture and oxygen in the environment, thus extending its service life.

1. Corrosion resistance

The main advantage of galvanized sheet metal is its excellent anti-corrosion properties. The presence of a zinc layer effectively resists oxidation and slows down the rusting process. Galvanized sheets perform particularly well in wet or chemically corrosive environments.

2. Economy

The relatively low cost of galvanized sheet metal makes it an important and economical material for many industries. The relative simplicity of the fabrication process and the low cost of production make galvanized sheet widely used in construction and manufacturing.

3. Machinability

Galvanized sheet is easy to process and can be cut, shaped and welded to suit different production needs.

II. Definition and Characteristics of PPGI White Sheet

PPGI whiteboard is a material made by applying a layer of high-quality coating on the basis of galvanized sheet. This coating not only increases the aesthetics, but also further enhances the protective properties.

1. Aesthetics

PPGI whiteboards are available in a wide range of colors and a variety of finishes, such as glossy, matte or textured, to meet the needs of different design styles. Whether it is used for building facade or interior decoration, PPGI can add visual appeal to the space.

2. Excellent weather resistance

The coating of PPGI material has good weatherability and UV resistance, which makes it less likely to fade and age in outdoor environments. This feature ensures the aesthetic appeal and durability of PPGI in long-term use.

3. Processability

Like galvanized sheets, PPGI white sheets have good processing properties and can be cut, stamped and welded. However, due to the presence of the coating, PPGI needs to be more careful during certain processing to avoid damaging the coating.

III. Comparison of application areas

1. Application of galvanized sheet

Galvanized sheet is widely used in the construction industry, such as roofing, walls and fences. It is also commonly used in automobile manufacturing, appliance housings and other industrial products, and is favored for its economy and good anti-corrosion properties.

2. Application of PPGI whiteboard

PPGI whiteboard is especially suitable for exterior decoration and appliance shells because of its aesthetic and weather resistance. It is commonly used in the exterior facade of modern buildings, interior wall decoration and furniture manufacturing, and can meet consumers' demand for personalized design.

IV. Summary

Galvanized sheet and PPGI whiteboard have their own advantages and disadvantages, the choice of which material should be based on specific application scenarios and needs to decide. Galvanized sheet with its superior corrosion resistance and economy, in many traditional industries still occupy a dominant position. PPGI whiteboard, on the other hand, has become an indispensable material in modern construction and appliance manufacturing due to its aesthetics and versatility. In practical applications, understanding their characteristics will help to better select the right material for optimal use.

Featured articles and news

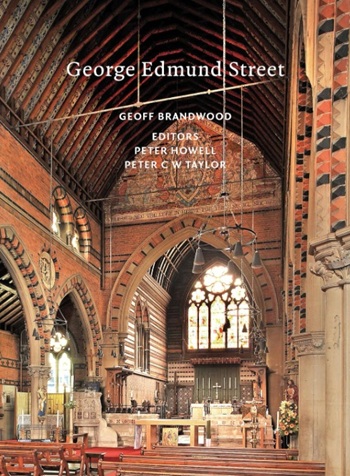

One of the most impressive Victorian architects. Book review.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.